Your advantages

Conformity: to the relevant standard procedures of the Karl Fischer regulation

Customized systems: put together your Karl Fischer measuring system according to your requirements

Over 25 years of experience: the manufacturer Nittoseiko (formerly Mitsubishi) has been a leader in Karl Fischer titration for over 25 years

Possible samples: organic and inorganic solids, liquids, gases, liquid gases and viscous samples

A wide range of applications: for example in the pharmaceutical industry, petrochemicals, energy, chemicals, food, food supplements, agriculture and wherever moisture occurs

Resource protection

Designed for longevity: robust workmanship, clear & simple handling, service and spare parts.

One example of the longevity of our products is the TOX-100 analyzer, which we sold from 1997 to 2013. Around 80% of these analyzers are still in use today – and are repaired, maintained and supplied with spare parts.

Sustainability: Compatibility with Karl Fischer measuring systems, reagent changers, burettes and additional measuring channels

Cost efficiency: offers options for high-throughput automation

Our service for you

Comprehensive training: we take over the induction of your employees

Also there for you after the purchase: many questions only arise during work. We are here to answer all your questions about the device and your measurement

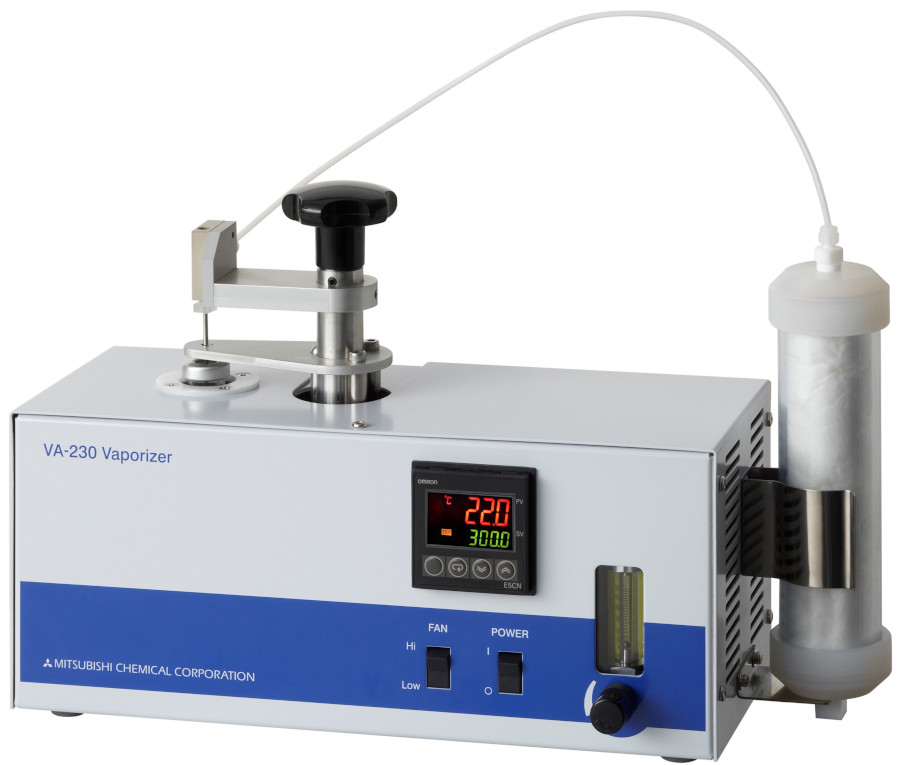

Full compatibility: with all Nittoseiko vaporizers

Unique: Karl Fischer measuring devices, sample introduction systems and reagents from a single source