Shelf life analysis: Use the oxidation test to determine how long samples containing fat remain fresh.

Possible samples: Food, cosmetics, industrial fats and much more

On-site analyses: quality and incoming goods inspection directly on your premises, whether you are a large corporation, medium-sized company or start-up

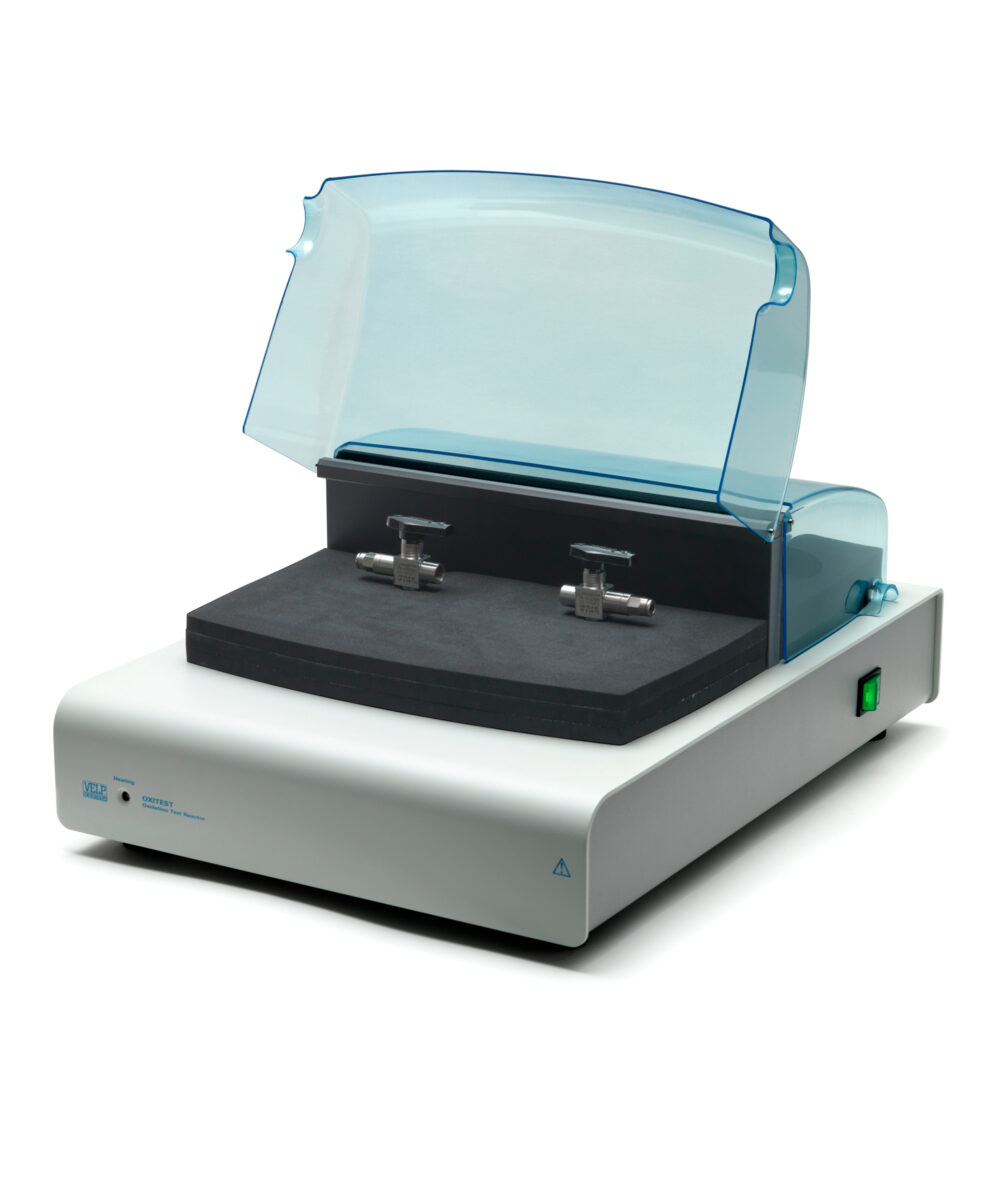

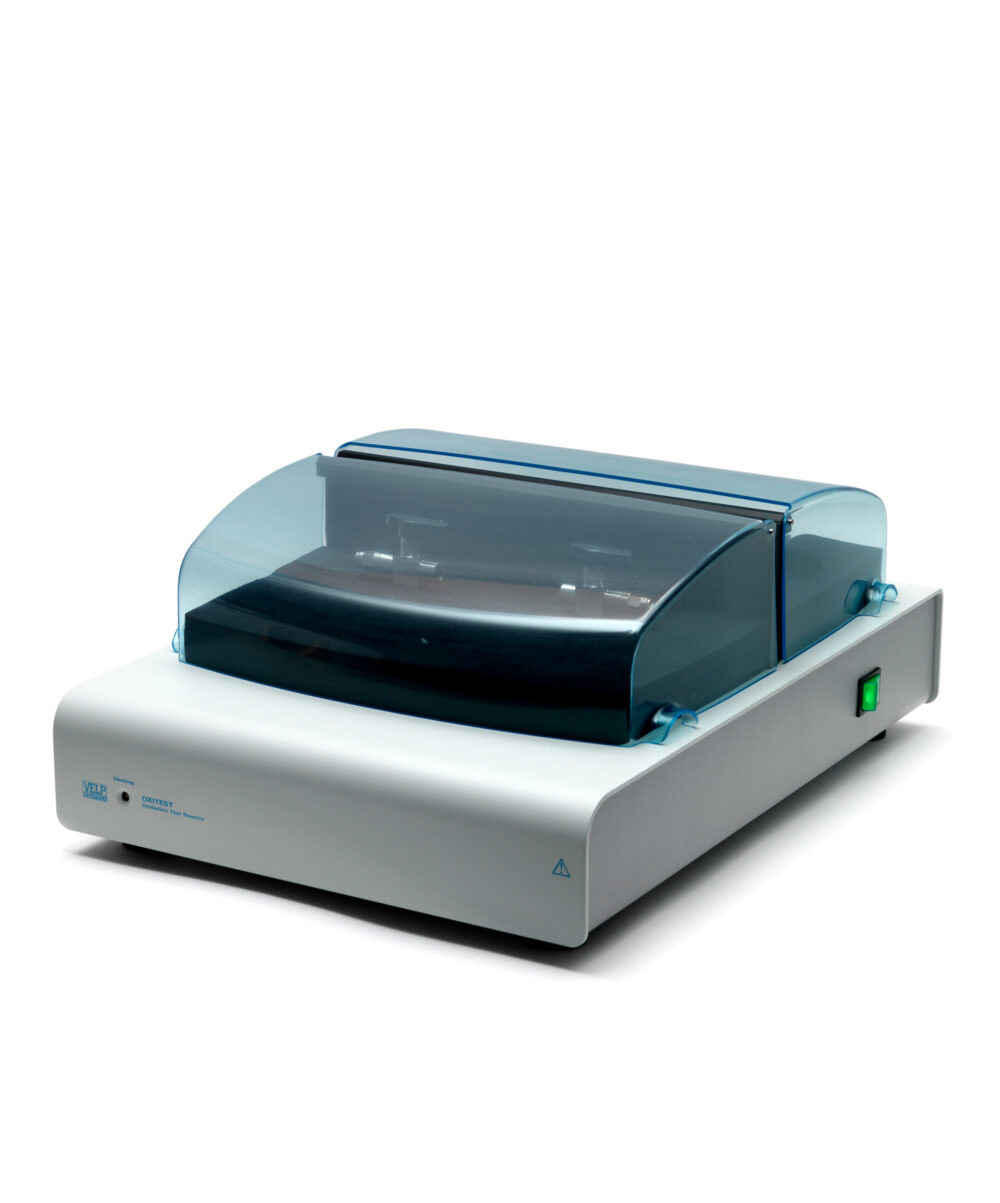

Also suitable for small rooms: The Oxitest is space-saving, making it suitable for installation in small, easily ventilated rooms

Independent analyses: stay flexible and simply carry out measurements yourself

Comprehensive training: we take care of training your employees on the Oxitest

Also there for you after the purchase: many questions only arise during work. We are here to answer all your questions about the device and your measurement

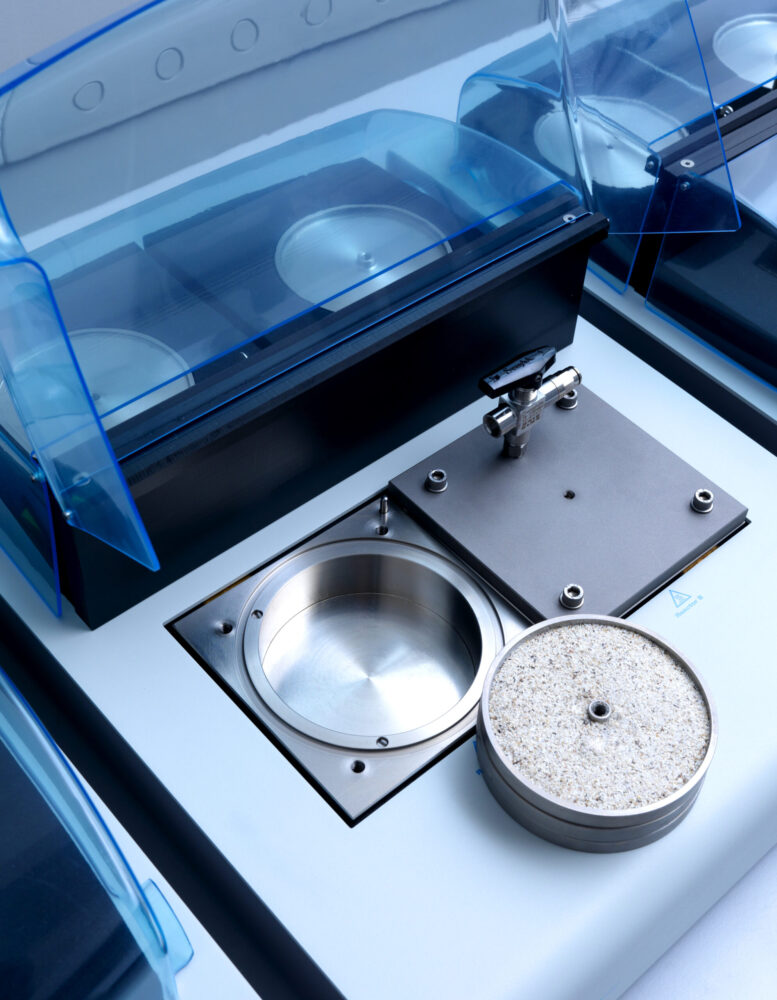

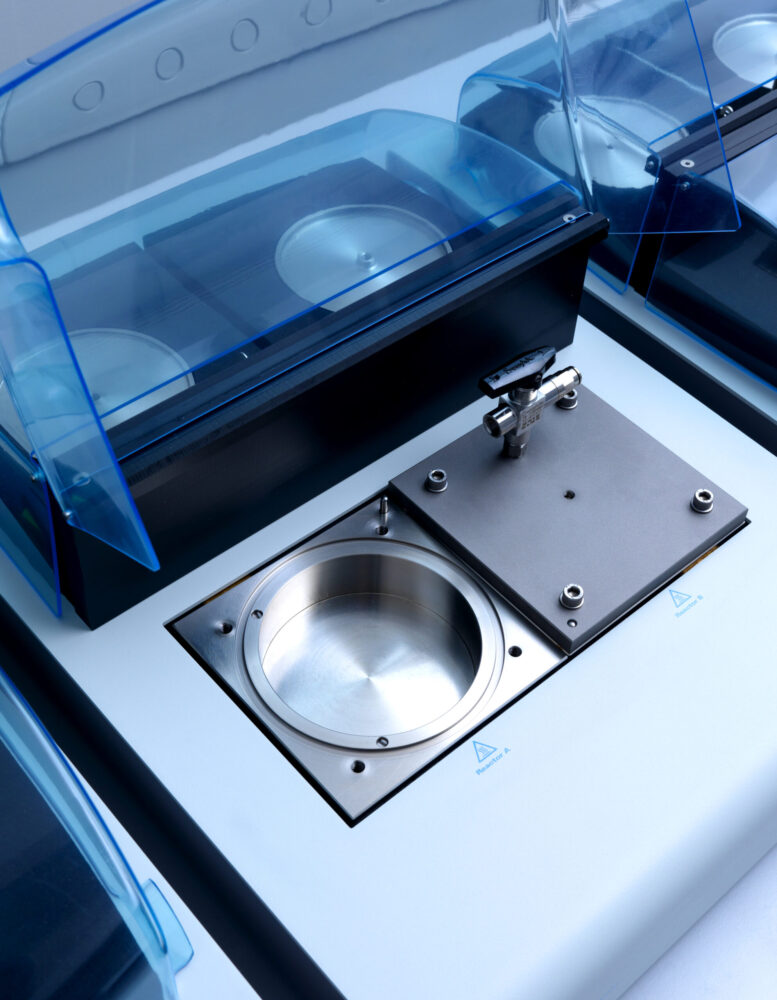

Time-saving sample preparation: Your samples, e.g. milk, butter, oils or creams, can be placed in the sample tray as they are. Only coarser samples, such as nuts, need to be ground so that they can be filled into the sample tray

Easy cleaning and maintenance: thanks to the robust design of the Oxitest

Compliance with the standard norm: the measuring method of the oxitest complies with the AOCS International Standard Procedure (Cd 12c-16)

Attractive price-performance ratio: the Oxitest leaves out all the non-essentials and focuses on the precise measurement of oxidation stability. This makes it easy to use, reliable and attractively priced!

Minimal use of resources: you only need a small amount of additional material (oxygen cylinder) for a measurement

A wide variety of applications: for example for

- Quality control

- Making transport and storage effects visible

- Studies on storage duration

- Product development

- Formula and recipe optimization

- Testing of ingredients

- Process optimization

- Packaging comparisons