Precision in the analysis.

Protection in use.

In addition to specialized analysis systems and protective devices, we also offer you individual advice – so that you are sure to make the right decision for the right system for every area of application.

Our team of experts from the technical-university sector is your long-term contact for your application, maintenance, service and quality assurance.

The requirements for laboratories, users and companies are diverse.

- Comply with environmental parameters

- Verify limit values of specific samples

- Adhere to and document defined measurement procedures

- Ensure safe workplaces without exposure to hazardous substances

- Prove productivity using laboratory tests

These requirements exist for good reason. After all, in addition to the comparability of data, it is often the protection of people and the environment that the standards and legally defined limit values are intended to safeguard.

Safe working environments and precise measurement results for different types of samples are therefore the measure of all things for us.

We support you in complying with these requirements

Our team of experienced application specialists will provide you with comprehensive advice on which analysis or containment system is ideal for your application.

A sustainable, safe solution and your long-term satisfaction are the focus of the entire consultation. Together, we ensure that you can comply with all the necessary regulations with the right application.

We support you with:

Consulting.

How we support you in your selection

Thanks to our customized analysis and containment solutions, standard-compliant sample analysis and the safety of laboratory staff are no cause for concern.

Our consultants have the relevant expertise and specialist knowledge to provide you with the best possible support in your decision-making process. You will receive through us:

Individual advice

Real specialists

Always up to date

Live demos

At your side for all questions

We provide comprehensive answers to your questions regarding the selection of suitable applications in order to support you in the decision-making process for an analyzer that is ready for long-term use or an efficient personal protection device.

Do you have very special requirements?

If a standardized solution is not an option, we will work out an individual solution for you, with which you can

- safely meet all standards

- protect yourself and your employees from exposure to hazardous substances,

- perform exactly the sample analyses that your company needs to fulfill your order.

Analysis and containment systems.

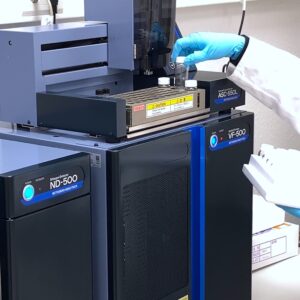

Our analysis systems.

Precisely measure, determine, analyze.

There is no room for deviations. You can rely on our analyzers to precisely determine the values for elemental and trace analysis, sum parameters or multi-parameter analysis.

Based on the advice of our technical specialists, you will acquire a device that precisely meets your analysis requirements. Whether solid, liquid, gaseous or pasty samples, we offer you analysis solutions in the following areas:

- AOX/EOX/POX determination

- Halogen and sulphur analysis

- Mercury analysis

- Karl Fischer titration

- CHNS-O Analytics

- PFAS determination

- Combustion IC

- Sample preparation systems

- and much more

Is the TOX-100 or AOX-200 analyzer also in your laboratory?

The TOX-100 appliance line was introduced in 1997 and replaced by its successor in 2013. The AOX-200 has been installed at customers since 2007. Nevertheless, thanks to the longevity of our products, around 80% of TOX-100 analyzers and around 90% of AOX-200 analyzers are still in use – and we still maintain, repair and respond to service requests for this line of devices today. As a matter of course.

Our containment systems.

Efficient protection.

In collaboration with the chemical and pharmaceutical industries, we have succeeded in developing open containment solutions that comply with an OEL of <100ng/m³. Our enclosures work with low, low-turbulence air flows that ensure both user protection and the functionality of the devices.

Optimum protective devices

- protect users from exposure to hazardous substances

- ensure the functionality of the applications and the equipment required for them

- offer you ergonomic laboratory workstations

- enable you to work efficiently

Our customers are impressed by our service & durable, low-maintenance systems

Intensive exchange that pays off

Get in touch with us. The data requested in the form is used exclusively to contact you in response to your request and helps us to provide you directly with the contact person with the appropriate technical expertise for the further process.

Your contact person will discuss your requirements and local working conditions with you. We work closely with you to evaluate which system configuration and settings are best suited to your application. This time-consuming configuration phase ensures that you make the right (purchase) decision.

During a demonstration of our systems – either at your premises or at our premises in Warrington – you can see for yourself how user-friendly and easy to operate our products are and clarify any questions that arise directly with our experts.

-

Make an inquiry

Use our contact form to let us know your requirements. Our team of experts will get back to you as soon as possible. -

Personal consultation

Together we clarify your specific needs and requirements for the analysis procedures. -

Product demonstration

Experience our analyzers live - at your premises or in our demonstration rooms. -

Individual offer

You receive a customized solution that fits your laboratory and your requirements exactly.

Get advice now - Contact us

Find the right elemental analyzer or containment system for your requirements. Our team of experts will support you in your selection and answer all your questions.

Use our contact form for a non-binding consultation or call us directly. We look forward to your inquiry!

Our international locations

Düsseldorf | Germany

Eichsfelder Straße 1

40595 Düsseldorf

- +49 (0)2 11 75 84 83 -0

Warrington | United Kingdom

910 Birchwood Boulevard

WA3 7QN Warrington

- +49 (0)2 11 75 84 83 -0

Paris | France

3-5 Rue Saint Georges

75009 Paris

- +49 (0)2 11 75 84 83 -0

Come and meet us!

We love the contact and exchange with you. This year we will be on the road again at many locations. We look forward to your visit!

Upcoming dates in 2025:

- September 10, 2025: Lab Supply Chemnitz, Germany

- September 23 - 25, 2025: Powtech Technopharm Nuremberg, Germany

- September 24, 2025: Lab Supply Leverkusen, Germany

- October 8, 2025: Lab Supply Hamburg, Germany

- November 12, 2025: Lab Supply Augsburg, Germany