Your advantages

Compliance with standard norms: Standard compliance with a variety of standard procedures

Only one injection setup: no matter for which sample

Best reproducibility and low scattering values for your measurement

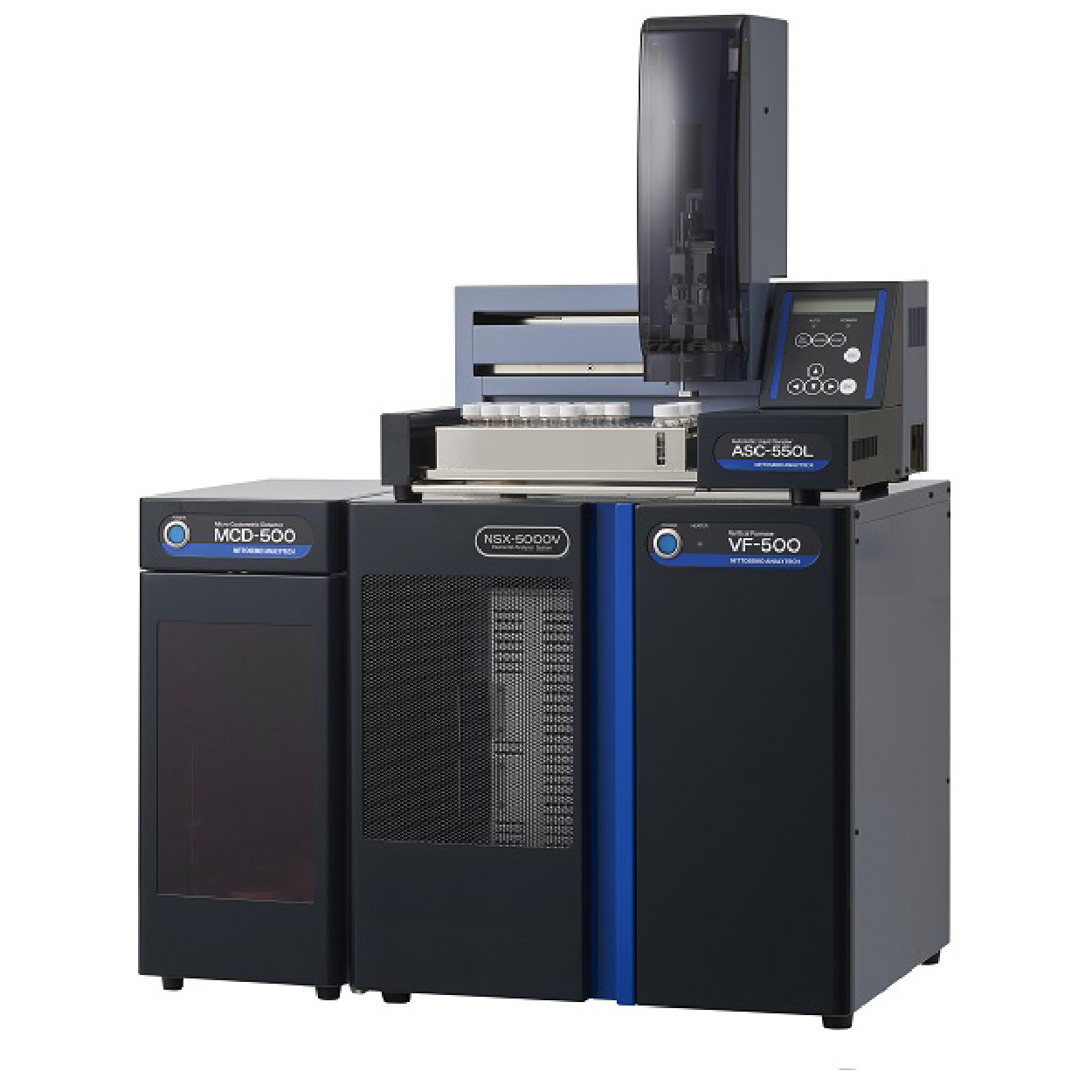

Modular system: offers the possibility to grow with your requirements

Measure halogens: easily expandable with a combustion IC to measure fluorine, bromine, chlorine and iodine

Micro coulometer: available, for simple chlorine determination

Flexible oven arrangement: either vertical arrangement for large sample volumes or horizontal for maximum flexibility

Resource protection

Designed for longevity: robust workmanship, clear & simple handling, service and spare parts.

One example of the longevity of our products is the TOX-100 analyzer, which we sold from 1997 to 2013. Today, 85% of these analyzers are still in use – and are repaired, maintained and supplied with spare parts.

Minimal use of resources: thanks to the sturdy design, there is less wear and tear and parts rarely need to be replaced

Cost efficiency: thanks to the patented Micro-Auto-Dilution function, which automatically dilutes samples and standards

Easy handling

Possible samples: for example diesel, gasoline, crude oil, lubricants

Ideal combustion conditions: for all substances

Consistent data and excellent results: despite different matrices and changing components

Easy cleaning and maintenance: thanks to the straightforward concept and robust design of the NSX-5000 components

Patented Micro-Auto-Dilution (MAD): samples and standards are automatically diluted inline during sample application

Intuitive software: including calibration and comprehensive reporting

A wide variety of applications: for example for

- Refineries

- (Petro-)chemical industry

- Environmental laboratories

Our service for you

A system just for you: maximum flexibility thanks to modular design and various sample loading, oven, detector and coupling modules

Comprehensive training: we take over the induction of your employees

Also there for you after the purchase: many questions only arise during work. We are here to answer all your questions about the device and your measurement

Support and spare parts: Even in 10 years from the time of purchase

20 years of know-how for your analytical problem: Benefit from over 20 years of experience and knowledge. We can help you, regardless of whether you want a special application, already have a device, want to expand your system or have to cope with new application requirements.